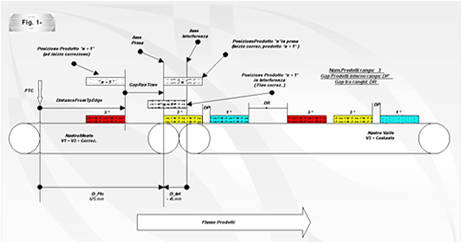

“The Art of Motion” derives by a thirty years old experience of Fabiano Manzan as well "motion control system integrator" and "packaging solution provider" in so-called “packaging valley” of Bologna (Italy).

The site proposes to give some indications on specific software applications of packaging fruit of experiences on packaging machines as well: wrapper, case packer, bundler, robot, pick & place,top loader, gantry, infeed unit and flow pack in various fields: pharmaceutical, tissue, food, cosmetic and others.