In any packaging automatic machines that make uses of a film unwinding with rotary roll and rotary knife the print centering procedure is very important in order to get a high quality of production.

The problem is to cut the film sheet always in the same point comparing with a spot position.

The first print centering solutions that appeared on automatic machines (before the servomotors) was adopting electro-mechanical devices that consist of a electromagnetic swicht that changed the ratio unwinding between two gears. The two gear provided to the unwinding two different value Lp+Delta and Lp-Delta where Lp is the nominal lenght sheet and Delta is a value of 0.2-0.3 mm.

The system was running in the following way:

every cycle on positive edge of a swich cam a photocell checks the spot, if the photocell was "ON" (checked the spot) the unwinding value must be Lp-Delta (in order to loose the spot) viceversa Lp+Delta.

That system was limited in number of correction per minute being an electro-mechanical system, further the tollerance of lenght among the sheets was a few millimeters.

In the last generation machine with servomotors the same servomotor that unwinds the film makes the print centering.

The procedure is the following:

1- We arm the registration (on knife position) of a photocell in order to check the spot.

2- When the spot is triggered we compare the registered knife position with a reference position and calculate the phase error with an unwinding formula.

3- We translate the phase error calculated in "degree" of knife to "mm" of sheet and launch a correction i.e. with an immediate cam once merging the gearing and scaling in a angle of master that we want.

That is the base concept but we can add some details:

a-Prepare the correct phase of the spot, homing the film before the start machine in order to have the first sheet basically in phase.

b- Calculate (during the functionament of the machine) with a filter PI the medium lenght between two consecutive spots.

c- Procedure to avoid the pictures reading between the spots.

d-To control if the spot was readed by the photocell every cycle and stop the machine if the reading has lost for more than "n" cycles.

Onother important thing is the following:

the cam profile of the knife must have the velocity during the cutting angle a little grater then the film velocity.

The last consideration:

The above algorithm runs well if we have the distance between two consecutive spot very constant viceversa the algorithm becames very instable.

To fix this case is better to work with the algorithm "FB_MultiplyCorrection" (see "Applications / MultiplyCorrection" sector on this web site.

Tip of the day:

If you are running with a print centering enable and the spot is continuosly lost, the first thing to do is disable the block of print centering and check if every cycle of knife the roll unwinds exactly the lenght of film required.

If the lenght of film is wrong, probably you have:

1- The ratio gear incorrect

2- Primitive diameter of roll incorrect

3- You have slicking between the roll and film

4- The feedConstant (ratio between counts/mm) of motor unwinding incorrect

If you do not start from this base condition any print centering algorithm will be very instable.

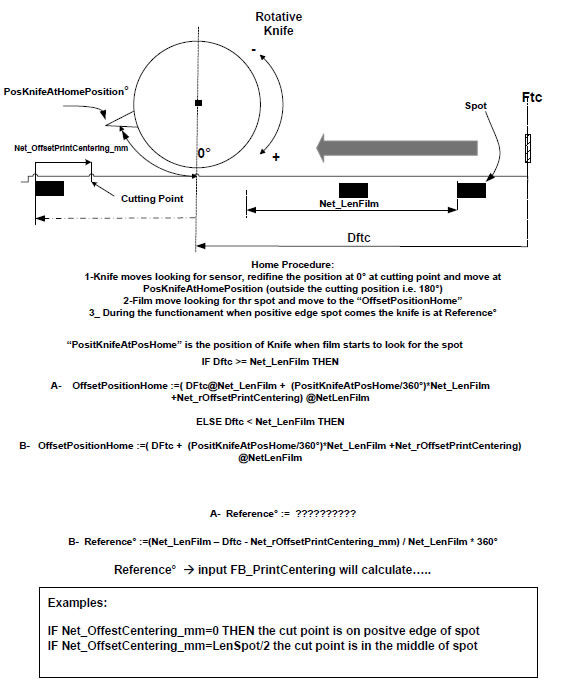

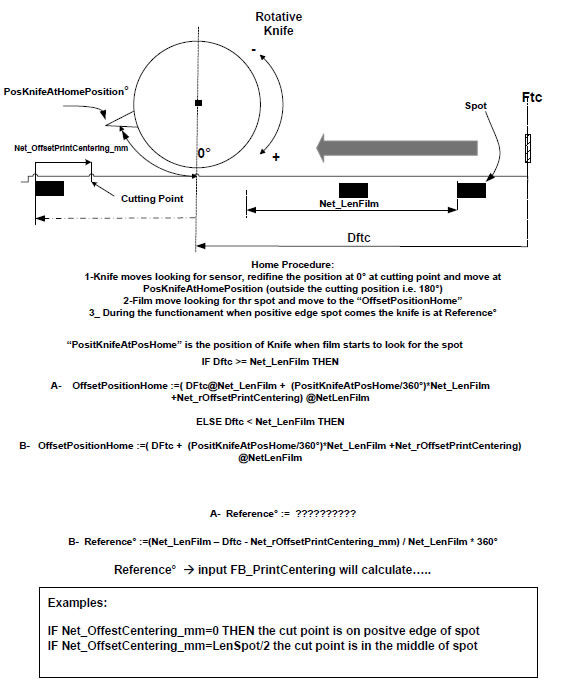

The concept of print centering is illustrated on Fig. 1

Fig. 1

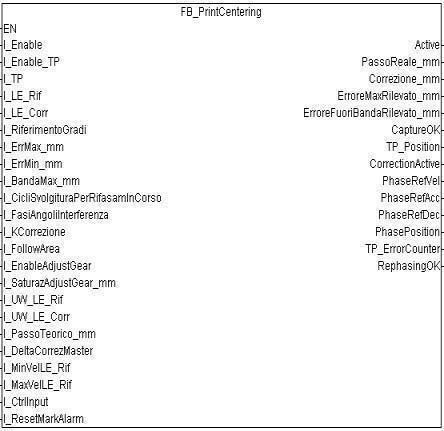

The algorithm "FB_PrintCentering" is at disposal and written by structured language (IEC1131) in a function block with "n" inputs and "m" outputs. (see below)

At to day this function block is available in version:

ELAU, Rockwell Automation, Siemens, Indramat, B&R and any other systems that uses language IEC1131.