During the functionament of a automatic machine with servomotors there are two critical situations.

1 - Immediate Emergency.

2 - Reset emergency.

To manage these two events generally we write a lot of instruction spreaded in the entire program in "ladder" or other language IEC61131.

This function block assembles all the controls that you need during an emergency and/or reset event.

When occurs an immediate emrgency we have to stop the machine (all the motors) in a time more short as possible compatible with safety guides and with inerzia of the mechanic devices.

Basically in emergency condition the machine stops in ~0.5s and anyway cut off the power within 1s (this time must short in order to protect the operator when he opens the guards.

If is not possible stop the machine in a very short time for inerzia problems you need to lock electromagnetically the guards until the power is cutted.

Follows the procedure during emergency:

1 Emergency occurs

2 Stop motor master within ~ 0.5s

3 Check at ~ 0.7s if all the motors have stopped

4 Feedback motors =OFF

5 Cut off the power

6 The safety circuit must cut off within 1s.

7 Check if safety circuit has cutted off within ~ 1.2s.

Follows the procedure during reset:

1 Alarms reset

2 Alarm clear

3 Check if any alarm is present

4 Reset safety circuit

5 Check if safety circuit is "ON"

6 Enable power to drivers

7 Check if the bus power is OK

8 Enable feedback ON for motors

9 Rephasing of the position of the motors depending of the position of their master

10 Machine ready to start

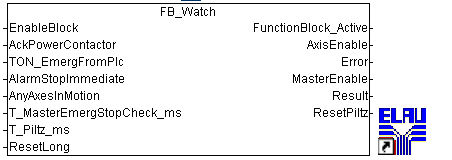

The algorithm “FB_ Watch” is at disposal and is written by structured language (IEC61131) and is used wth a function block with n inputs and m outputs. (see below)

At to day this function block is available in version:

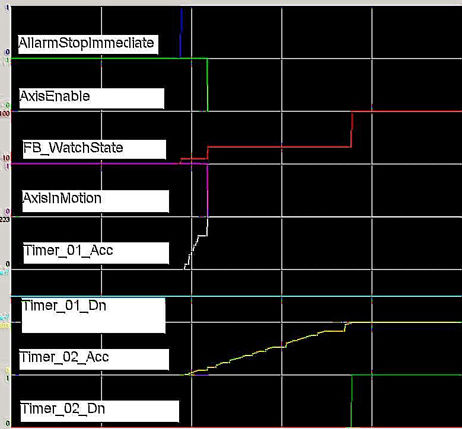

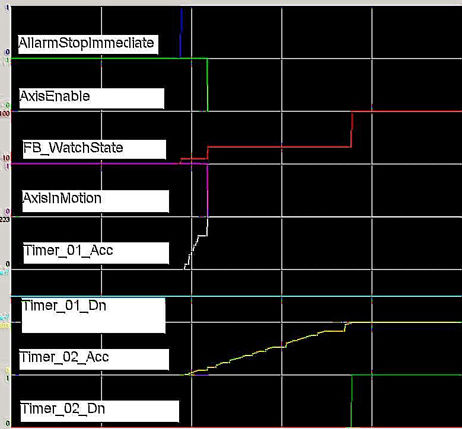

Emergency procedure:

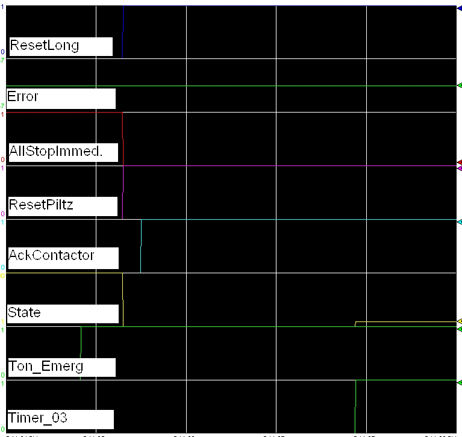

Reset procedure:

“ FB_Watch ”:

ELAU, Rockwell Automation, Siemens, Indramat, B&R and any other system that uses language IEC1131.